- Whatsapp: +8618867802069

- Email: [email protected]

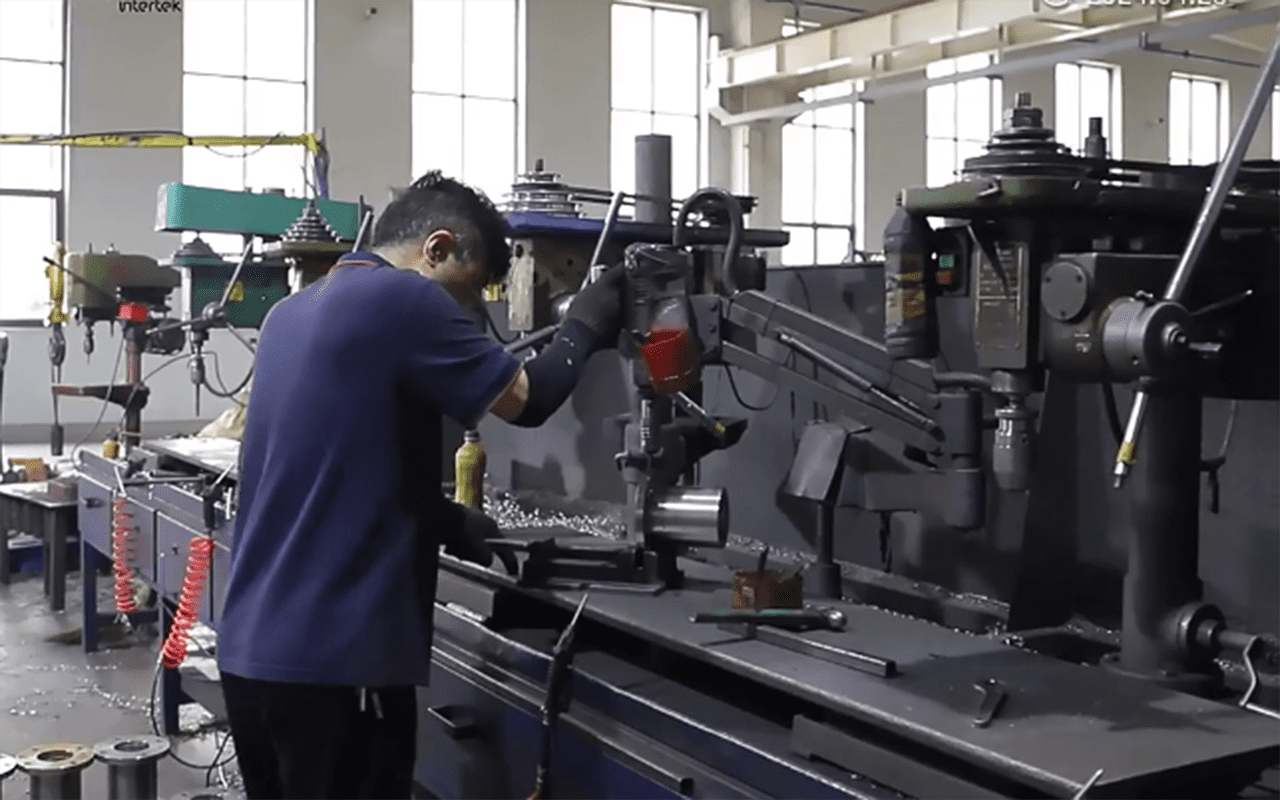

Thinki slitting machine is equipped with intelligent operating system, the operation interface is simple and intuitive, workers only need to input scuttling size, quantity and other parameters on the touch screen, the equipment can automatically complete the accurate setting, fast response to production instructions. At the same time, the use of advanced photoelectric tracking technology, real-time monitoring of material position, automatic adjustment of slitter tool position, slitter accuracy up to ±0.2, to meet a variety of high-precision slitter needs, whether it is paper, film or cloth and other coil, can achieve the complete cent cutting.

| Item | our offer |

| MOQ | 1 set |

| Leading times | 30 working days, depending on the qtys |

| Main product | slitting machine |

| Customize logo | Accept |

| Warranty | 1 year |

A slitting machine is a device used to cut wide rolls (such as paper, film, metal foil, fabric, etc.) into strips according to a set width. It is widely used in industries such as packaging, printing, electronics and textiles, which can improve the utilization rate of materials and meet different production demands.

Check the equipment status: Ensure that all components of the machine (tools, guide rails, air pressure, etc.) are normal, without any looseness or damage.

Select the appropriate tool: Choose a suitable round or straight tool based on the material type (such as film, paper, etc.) and adjust the tool distance.

Set the slitting parameters: Enter parameters such as slitting width, tension, and speed in the control panel.

Loading: Correctly install the raw material rolls on the unwinding reel and adjust the deviation correction system to ensure that the materials are centered.

Startup: Turn on the power, conduct a self-check of the equipment, and confirm that there is no alarm prompt.

Material threading: Pull the material through the deviation correction device, the slitting frame, and fix it on the winding reel.

Test cutting: Run the machine at low speed, observe the slitting effect, adjust the tension or the position of the tool to ensure neat slitting without burrs.

Formal production: After confirming that there are no errors, increase to the normal production speed and monitor the slitting quality in real time.

Winding: After the slitting is completed, stop the machine, remove the finished coil, and conduct a quality inspection

Privacy Policy | SiteMap

Copyright Wenzhou Thinki Machinery Co., Ltd.