- Whatsapp: +8618867802069

- Email: [email protected]

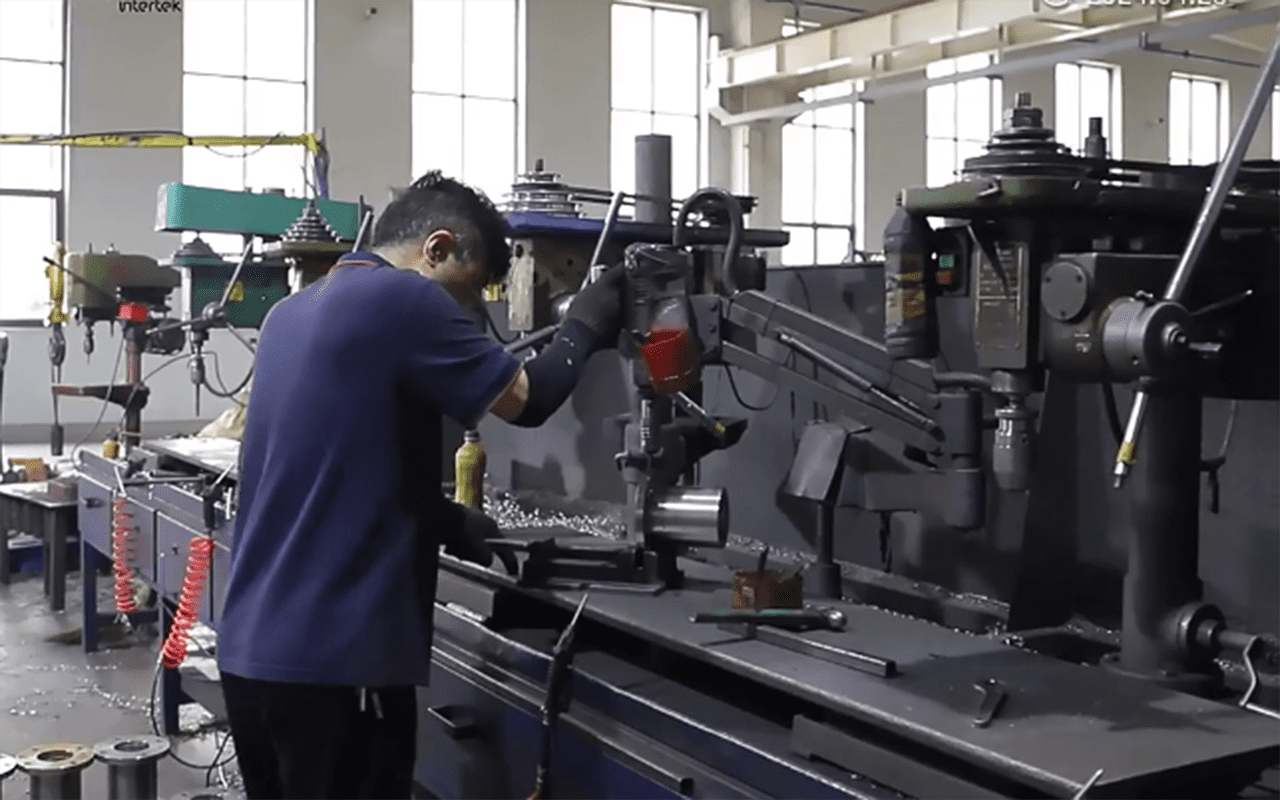

Thinki sheet cutting machine equipped with advanced intelligent control system, easy to operate. Operators only need to enter parameters such as cutting length and quantity on the intuitive operation interface, and the device can respond quickly and execute accurately. The equipment uses high-precision sensors and servo motors to monitor and adjust the cutting position in real time to ensure that the accuracy of each sheet cutting can be controlled within ±0.2 mm, effectively reducing material waste and improving product quality. Whether it is paper, film or cloth and other coil materials, it can achieve complete cent cutting.

| Item | our offer |

| MOQ | 1 set |

| Leading times | 30 working days, depending on the qtys |

| Main product | slitting machine |

| Customize logo | Accept |

| Warranty | 1 year |

A sheet cutting machine is a device used to cut rolls (such as paper, film, metal foil, self-adhesive labels, etc.) horizontally to a set length. It is widely used in industries such as packaging, printing, labeling, and building materials, and can slit continuous rolls into single sheets or sheets of specific lengths.

Check the equipment status: Confirm that the cutting tools are sharp, the mechanical parts are not loose, and the pneumatic/hydraulic system is normal.

Select the appropriate cutting tools: Choose the suitable blades (such as flat knives, round knives, serrated knives, etc.) based on the thickness and hardness of the material.

Set cutting parameters: Enter parameters such as cutting length, speed, tension and count in the control panel.

Loading: Correctly install the coil on the unwinding reel, adjust the deviation correction device (if any), and ensure that the material is conveyed in the center.

Startup: Turn on the power and perform a system self-check to ensure there are no fault alarms.

Feeding: Pull the material through the deviation correction system and the feeding roller, and ensure its smooth entry into the cutting area.

Test cutting: Run the machine at a low speed, observe the cutting accuracy, adjust the knife pressure or feeding speed, and ensure that the cut edge is neat and free of burrs.

Formal production: After confirming that there are no errors, increase to the normal production speed and monitor the cutting quality in real time.

Receiving/Stacking: The cut sheet materials are automatically stacked or conveyed to the designated location. The operator needs to regularly check the neatness of the stacking.

Privacy Policy | SiteMap

Copyright Wenzhou Thinki Machinery Co., Ltd.